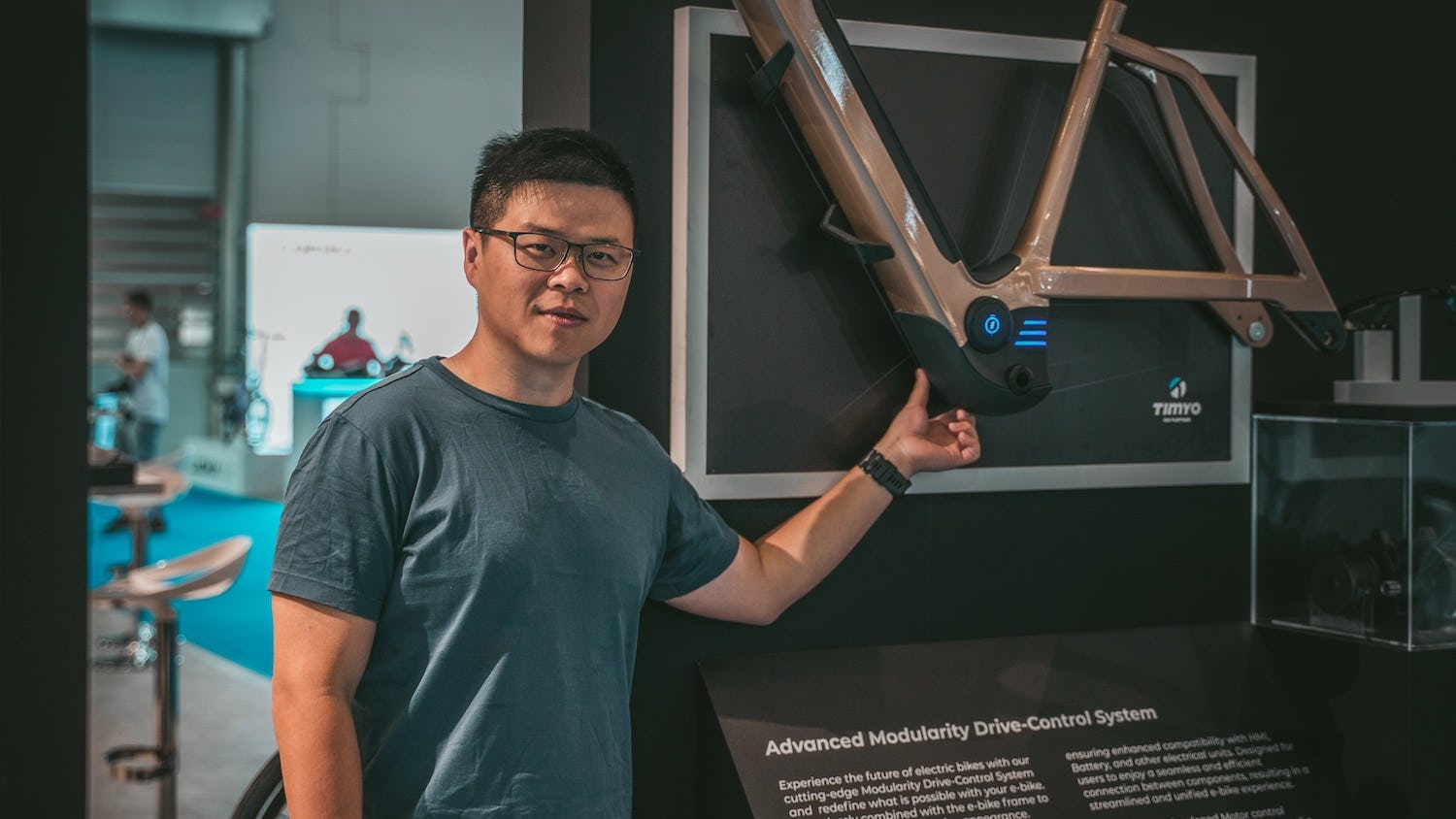

“We see ourselves as trendsetters,” Timyo’s CEO, Steve Zhu, said during an interview at Eurobike show in Frankfurt, referring to the newest innovation of his company that was presented on a specially designed wall at the Timyo booth: a golden frame with a sleek and cohesive design, including a fully integrated drive unit from Timyo’s own brand Kreutzer Systems.

“With this project study, we are showing what the future will offer. Our electric bicycles will be so much more than just bicycles with electric assistance. They will fill a new category in the field of mobility – or as we call it: Human Machine Interfaces,” Zhu said, adding that Timyo’s newest development is also a symbol of the journey the company has undertaken. “We are no longer an assembler or a bicycle producer. We are now an R&D-driven high-tech company – and want to share that with the public.”

An impressive transformation process

Indeed, the company has embarked on an impressive transformation process over the past few years. Since its foundation in 2015, Timyo has not only developed into an international player, but also quickly earned a reputation for producing high-performance, stylish electric bikes that cater to a wide variety of users. Combining sleek design with functionality, the company’s bikes – mainly distributed under its brands Van Dijck, Keola and Muon – have become popular choices for commuters, leisure riders, and fitness enthusiasts alike.

With the start of the COVID-19 pandemic and the associated supply shortages, however, Zhu made the crucial decision to rebuild his company into a trailblazing high-tech firm. “We began this transformation back in 2021, born out of supply chain limitations and technical difficulties with batteries and engines that hampered our progress. These difficulties spurred us to take control of the supply chain and specifications. A step that also created the basis for us to have significantly more freedom in our developments and to fully realise our innovative potential,” Zhu explained during the Eurobike interview.

From Timyo to Timyo 2.0

One notable outcome of this move is the Kreutzer engine, an in-house developed power unit that is powering many of the Van Dijck, Keola and Muon that have been showcased at this year’s Eurobike. “Kreutzer is a good example of our company’s path,” Zhu said. “The first generation was an OEM engine labelled under our name. Our new Kreutzer 2.0 engine, however, is a completely in-house developed power unit which combines the durability of an e-cargo gearbox while retaining the smoothness of an e-bike engine,” he continued.

This impressive transformation, achieved within a few years, is the reason why Zhu also referred to Timyo as Timyo 2.0 during Eurobike. For Zhu, the golden frame with the fully integrated drive unit from Timyo’s own brand Kreutzer marks only the beginning of a new chapter in the company’s history: taking the next step forward, Timyo is set to bridge the gap between the bicycle industry and other sectors, he revealed.

“By being not a bicycle company but a hightech company, we will have plenty of options in the upcoming years,” Zhu said. It was therefore more than suitable that the golden project study on the Timyo booth was emblazoned with the meaningful slogan: “Timyo Future”.

This article is sponsored by Timyo.