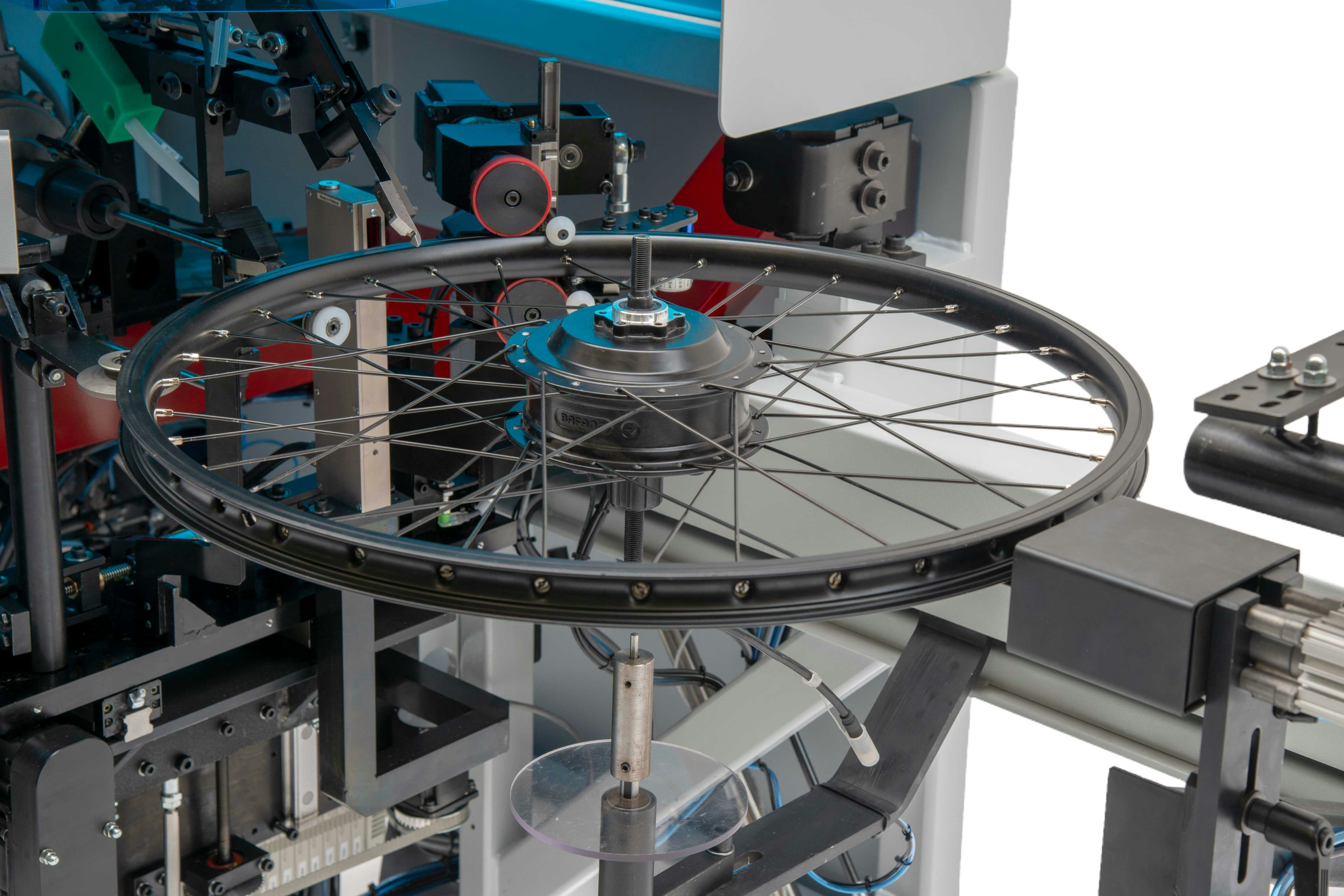

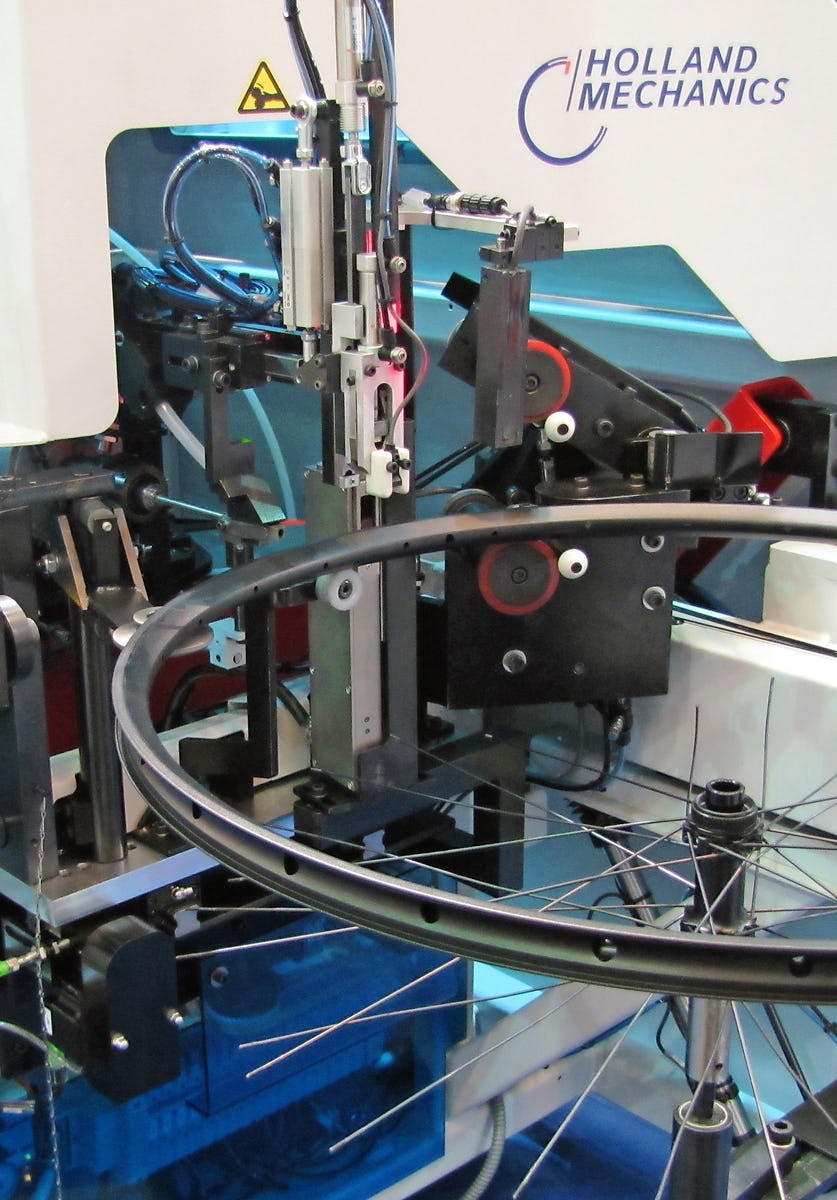

The Inline Lacer takes the spokes from the hub to the rim and then winds-up with a set amount of revolutions, and the Robot SG aligns the wheel. “This combination is the most flexible on the market,” says Jim Smits from Holland Mechanics.

“The Inline Lacer has a movable arm where the X and Y axes can move. This way, the machine can position the spoke nipple in line with the spoke angle, ensuring optimum contact."

Each wheel is produced in the same way, in just a few minutes”

All wheel sizes

Bicycle manufacturers have to deal with various e-bikes and wheel sizes. The machines can automatically adjust to suit the wheel size to be produced. With one press of a button the Inline Lacer can adjust to suit a different wheel size.

The Robot SG scans the incoming wheel and automatically adjusts accordingly. This quick adjustment makes factory work considerably more efficient.

Massage techniques

The machines offer various features. For example, the Robot SG has a cable tray option for e-bike wheels with a hub motor that locks the cable from the hub. The cable is therefore never interfering the trueing process.

Furthermore, the Robot SG offers an optional stabilizing function to improve quality and with this, the neck and spoke nipple are better positioned in the wheel. Thanks to the massage technique the first bicycle rides are simulated, and the consumer will have no problems with loose spokes.

Constant quality

“For e-bike manufacturers, the Inline Lacer and Robot SG are ideal, since both ensure constant wheel quality. "Each wheel is produced in the same way, in just a few minutes," says Smits, emphasising the importance of a good wheel for e-bikes. "A rim width of 40 to 50 mm becomes the standard for e-bikes. The bikes are somewhat heavier and therefore a decent quality is needed to limit warranty issues."

Wheel data in the database

The machine keeps track of all relevant production data in a linked database - including how the wheel is made and how the tension is distributed. A QR code can be placed on the wheel and it’s easy to see the history of the wheel in the event of a warranty issue.

"If there is a discussion about quality of the e-bike wheel - there is proof of how the wheel was produced and its journey. This will put an end to any reservations when discussing quality."

This article is sponsored by Holland Mechanics.