Tektro Europe GmbH, part of Tektro Technology Corp, was officially established in September 2019. From this German office, located an hour's drive from Frankfurt, Tektro is strategically in contact with the key European partners such as OEs, DIs, dealers and media. General Manager Thomas Lattke, who joined Tektro 2019 in February, sees that establishing the European office on Central Europe soil has been an important strategic move to build trust and be present in the most important markets. Particularly in the field of e-bikes, which often requires extra powerful braking systems, customised projects with OEs are steadily taking shape. A key lighthouse project with Riese & Müller has been important in this respect.

Market research

“When we officially launched our mission in 2019, we looked at European needs in conjunction with market research. “After Riese & Müller were reaching out to us with the inquiry of special needs for the e-cargo category, we saw the rapid rise of commuting and e-cargo.” There were opportunities for us by partnering, as with Tektro and TRP E Bike Solutions we have the perfect technology for heavy duty application,” says Thomas Lattke.

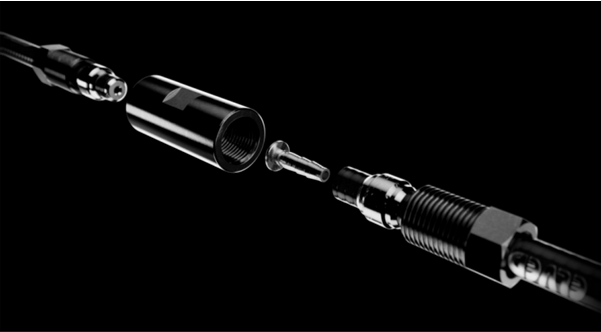

“We have developed the TRP C 2.3 brake system, with our heart-piece the 2.3 mm strong rotors for greater lateral stiffness and heat stability, a strong 4 piston calliper and specific front brake hoses, suitable for heavy duty e-cargo bikes. The R&M LOAD 75 S-Pedelec can weigh up to 200 kg with speeds of 45km/h plus. Safety and reliability were key for founder and CEO Markus Riese. We knew beforehand: if we cooperate with a premium brand like Riese & Müller and deliver, it will reflect positively on our brand reputation. Riese & Müller is a market leader in e-mobility.”

Prestigious projects

In the sequel, Tektro has worked on several prestigious projects. For example, Lattke is proud of the recently launched Concept Dynamic Cargo by CUBE and BMW, a three-wheeled electric bicycle, which was launched at IAA Mobility. For this, the updated Tektro Auriga Twin Plus was specifically developed. “This is a so-called multi lane application. The purpose of this is that, when braking, you simultaneously control two callipers at the rear with one brake lever, additionally the brake has an integrated parking mechanism when the bike is standing. With a Long John or the Riese & Müller Load, for example, which is a single lane application, this is not required,” says Lattke. “Solutions come naturally as soon as challenges arise,” he adds.

Another strength of the E Bike Solutions programs are dedicated projects to single brands. In various scenarios, they are widely accessible to all OEs. “If it is a customised project, then it is more or less exclusive to a dedicated time. Take the Canyon Precede On for example: we developed an integrated lever unit for Canyon. Canyon provided us with the handlebar design, and we used it as a basis for incorporating the brake technology. If you look at the handlebars, you can only see the lever blades sticking out of the cockpit. The rest is hidden in the Canyon made cockpit. The Tektro R&D team values these projects as they help both sides to learn and grow.”

Agile team

Such customised projects often take one and a half to two years, depending on the complexity. For example, the solution for the Riese & Müller Load involved six team members, including a dedicated application engineer who was in charge. “We are an agile team of capable product, project and engineering talents. That makes us flexible and ensures that we can act quickly. It's a matter of putting the right people in the right spot,” says Lattke. “The development section is mainly located in Taiwan. We have an engineering set-up in Changhua, where our two factories are also located. In Taichung is the R&D department. I am now the extended eyes, ears and hands in Europe, which helps a lot.”

Tektro foresees further market growth for specific braking systems designed for e-bikes and e-mobility vehicles. “The European market is heading towards 30 million bicycles by 2030. By far the largest proportion of these bikes will be electrically-assisted. The e-mobility market is growing, pushed by new SUVs categories (e-MTBs with fenders, carrier & light) and four-wheeled vehicles with electric motors that are sometimes loaded with 250 kg plus are starting to become more popular, especially through delivery services. This is where the opportunities for Tektro and TRP lie. At the same time, we need to focus as a company. Especially the Tektro Europe Team will be working close with strategical partners and finding the right solution for them by listening carefully and continually doing research. We listen and look very carefully at what we can do from a European perspective.”

Steady growth

Tektro's development of innovative products and steady growth also means more pressure on the aftermarket side of the market. “We are building up our service hub. The key mission of that department is to be, first and foremost, back-up for the OEs and distributors. We help our existing partners and guide them with training and workshops. They have to be able to do it themselves. Especially now that Tektro Europe is on the rise and the demand for our solutions is increasing, we have to be very alert. As of 1 January, the service team will welcome two additional full-time colleagues. This is in line with the current and further growing market demand. The two main areas of smart E Bike Solutions to contribute the growing e-mobility segment and customer service will keep us busy and we are excited to be a key part of this important segment.”

This article is sponsored by Tektro.