As a result of COVID-19, the supply chain has been totally affected; the supply cuts, the increase in transport costs and the increase on the demand has caused manufacturers of electric bicycles to consider the development of new projects within Europe. This dynamic is there since the Eurobike in September 2021 that took place in Friedichshafen, Germany.

Growth of light mobility users

At the same time, an increase in awareness of environmental sustainability has led European cities to take big steps forward towards adapting their infrastructures and facilitating the increase of light mobility users.

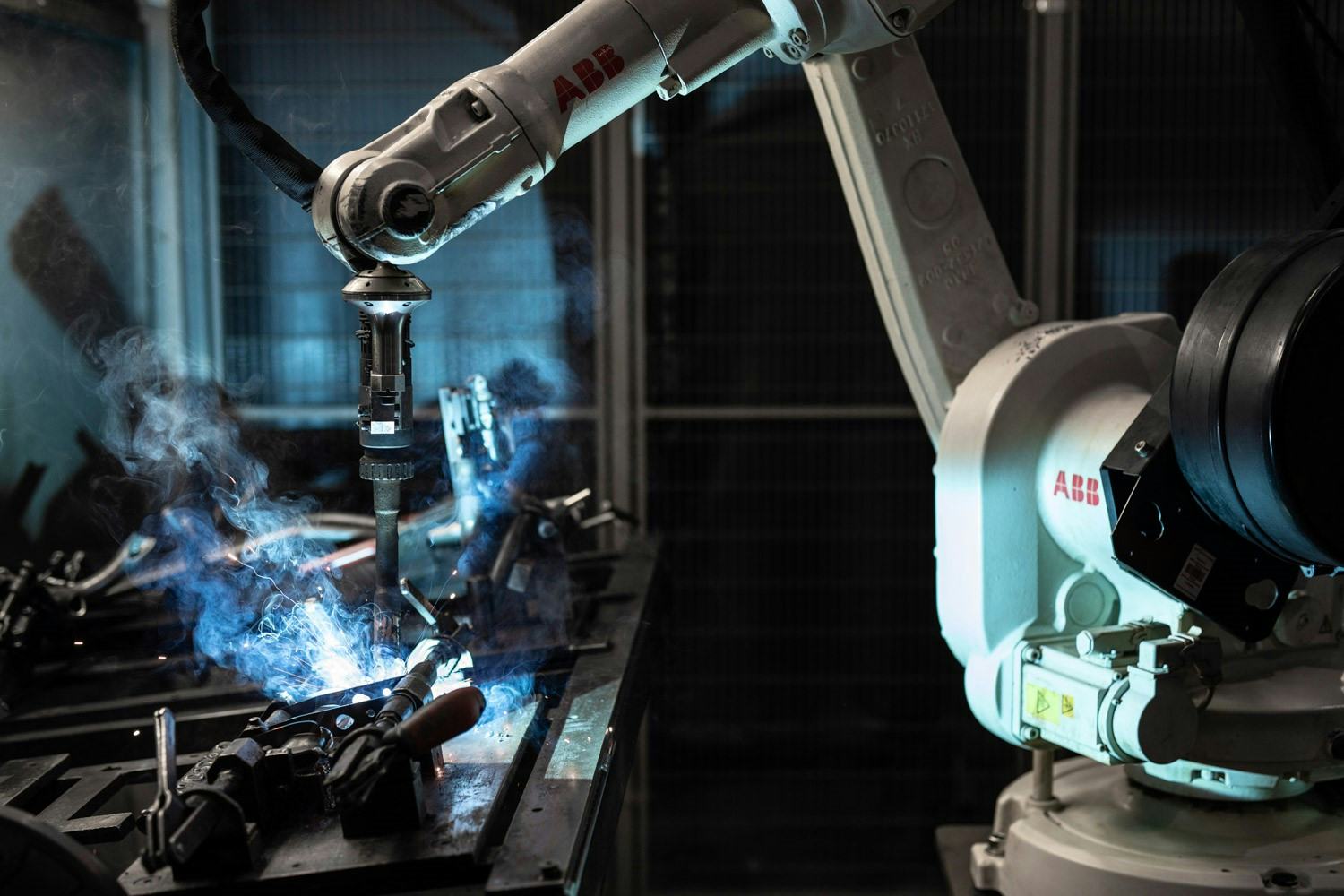

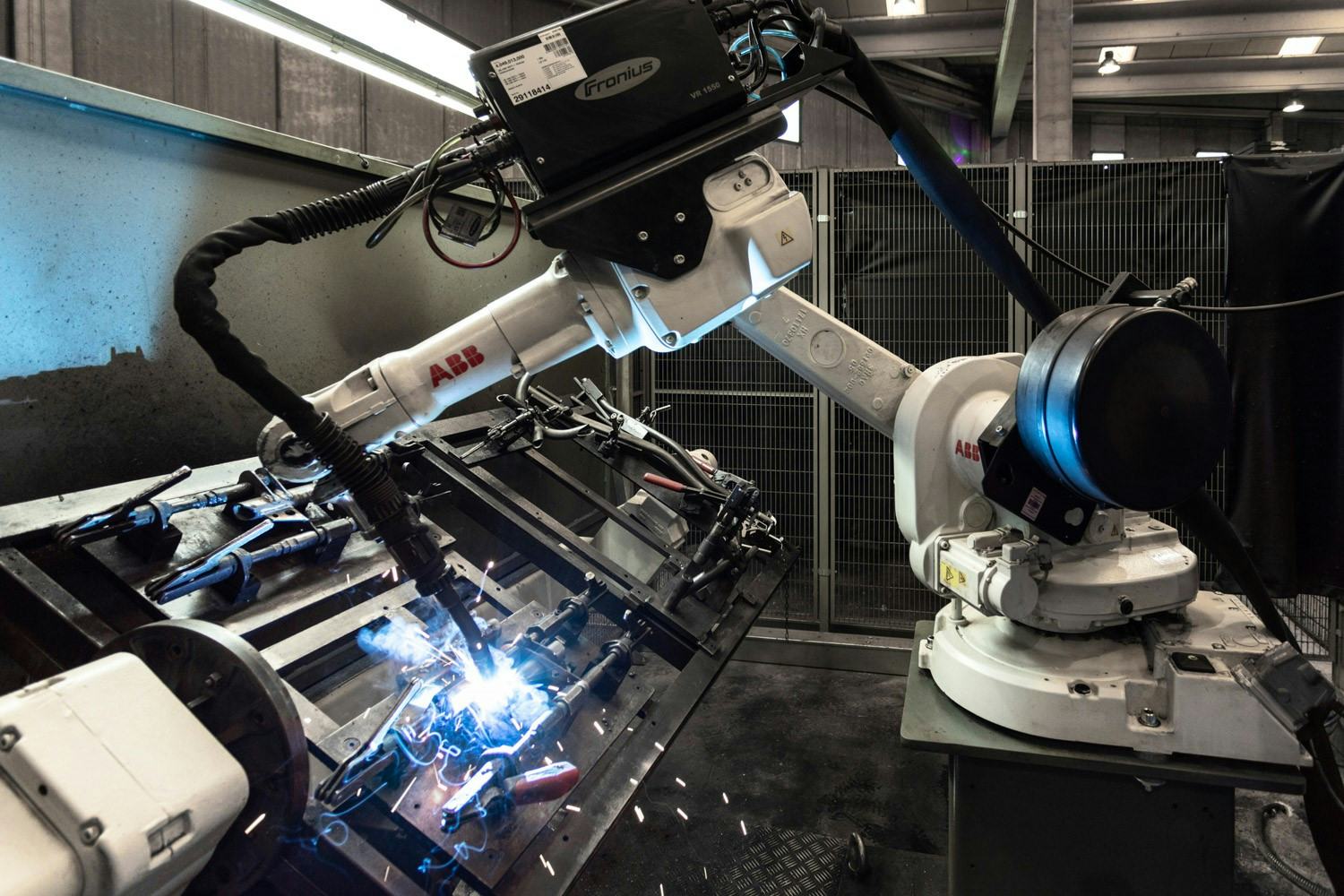

Frames and racks

For companies such as Derivados del Motor, located in Spain, it has meant an increase in the demand for manufacturing frames and racks. The robotisation of the welding process is key to being able to meet this high demand in the e-bike sector, to improve the competitiveness of the products and the optimisation of the entire production process, affecting the final cost of the parts.

A highly qualified team is required in all production processes ”

Adaptation

The relocation of these productions to Europe cannot be implemented in a short time, a period of investment and adaptation of the existing resources is needed. However, for a company with extensive experience of more than 49 years, this adaptation could be done in a shorter period. Evidence of this are the new productions of Ecargo models and their parts for this 2022 season.

Highly qualified team

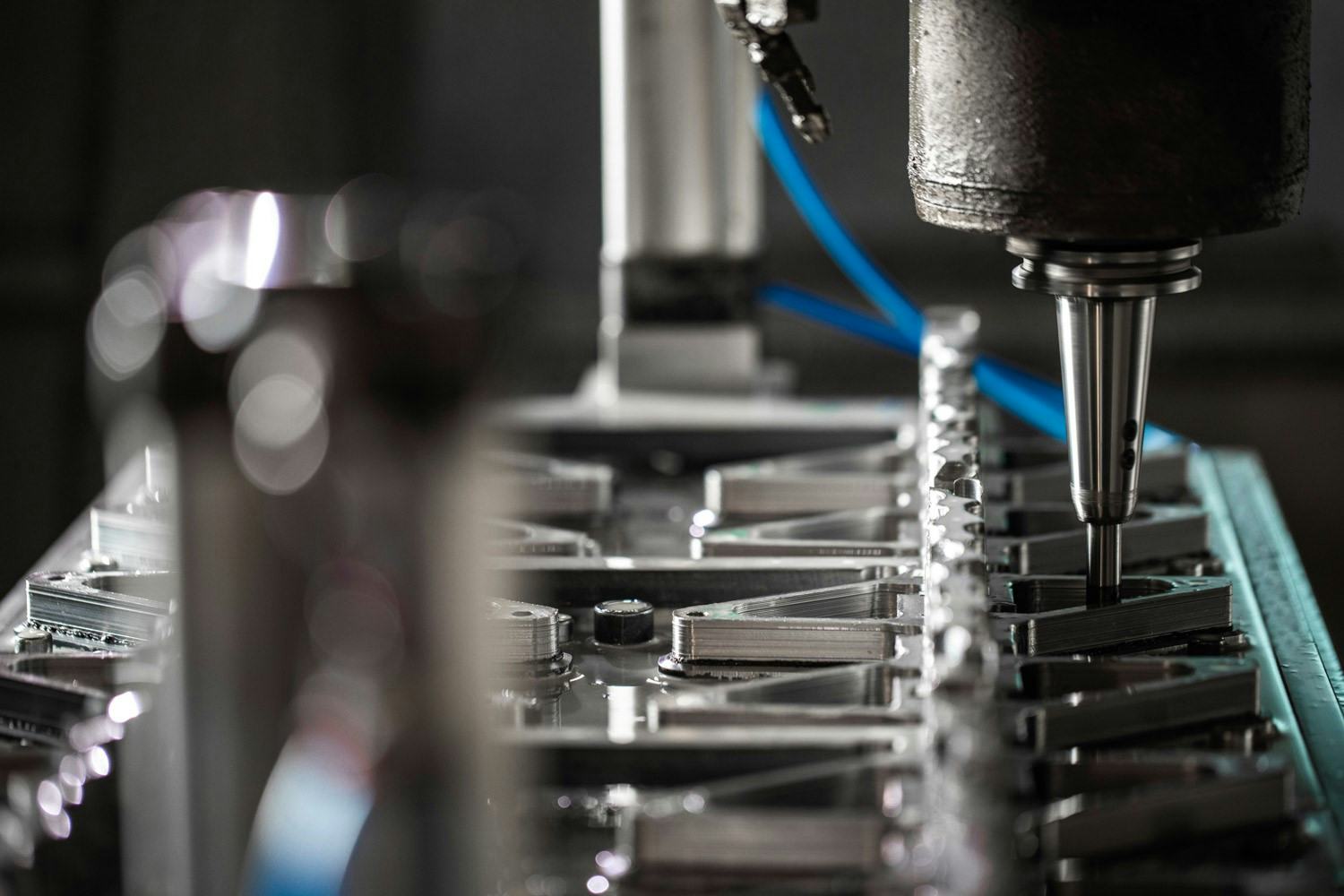

A highly qualified team is required in all production processes such as laser cutting; stamping; bending; hand/manual welding; robotic/automatic welding; heat treatment; sand blasting; and painting. Solutions can be found for all technical needs of this type of product. In Europe, there is a wide range of possibilities for welding types, such as MIG & TIG, and for the diversity of materials, such as aluminum, steel or titanium.

Industrialisation

Other added values are the possibilities of industrialisation that could be adapted to the volumes of each specific customer. The tools can be mechanic or automatic, depending on the specifications of the project. With a correct industrialisation, the geometry of the frame in all the units produced over time can be guaranteed.

Hydro-formed parts

Currently, the only handicap in Europe is the production of hydro-formed parts, because this kind of industry is oriented towards the automotive sector. Although in recent months the e-bike industry has showed interest due to the increase in business volume in the last year.

In addition to all the above, we cannot ignore the growth of domestic consumption in Asian countries. This growth is one more indicator of the need to have suppliers within our borders that can guarantee the supply of all the components for a sector such as the e-bike industry in the coming years.

Ensuring the supply of components and parts for e-bikes in Europe is the key to success in a business based on purchasing and supply management.

This article was sponsored by Derivados del Motor