SKS Germany, an abbreviation of Scheffer-Klute Sundern, is the success story of a family business. The fourth generation is now at the helm. It still produces air pumps, which is where its great success began. The Rennkompressor is undoubtedly the best known of all. In the eighties, mudguards were added. In the meantime, the range has expanded to include tools, handlebar holders, saddle bags and other practical trinkets. Everything is produced in Germany for maximum reliability and innovation.

In what way is the topic of sustainability embedded in production in Germany?

“At SKS Germany, we consider sustainability extremely important. Our motto is not for nothing: Wertschätzen statt wegwerfen. That means: value raw materials and don't just throw them away. When I look at our product range, I see very durable, quality products. They avoid wasting raw materials. Resources are saved in this way. In product development, for example, it is an important criterion that our technologies are always repairable. In addition, they are replaceable, if necessary even many years after purchase.”

How challenging is it to be innovative with products that are not very sexy at first glance?

“If you need a pump, you have a flat tyre. And if you are looking for a mudguard, the weather conditions are probably bad. The reason for using these products does not make them very sexy. And yet you see developments that do give our categories a sexy image. They are becoming more design products, everything on and off the bike has to be beautiful. You can see that in the mudguards, for example. De Speedrocker and the Mudrocker mudguards sets are good examples of this. We pay more and more attention to the combination of functionality and design. Because a product that functions well but doesn't look good on the bike, doesn't sell."

How do you organise the innovation process?

“We have an innovation team that focuses purely on innovation and new developments. We also have a separate R&D department that deals with specific innovation themes. Digitalisation, for example. When innovating, we include the wishes and suggestions of our direct customers. We pick up their suggestions at international trade fairs and events. In addition, we receive feedback online and from professional athletes whom we support with products. Feedback enables us to generate new ideas and further develop existing products. In this way, we meet the various demands of the market.”

In which corner are you currently looking for the biggest innovations?

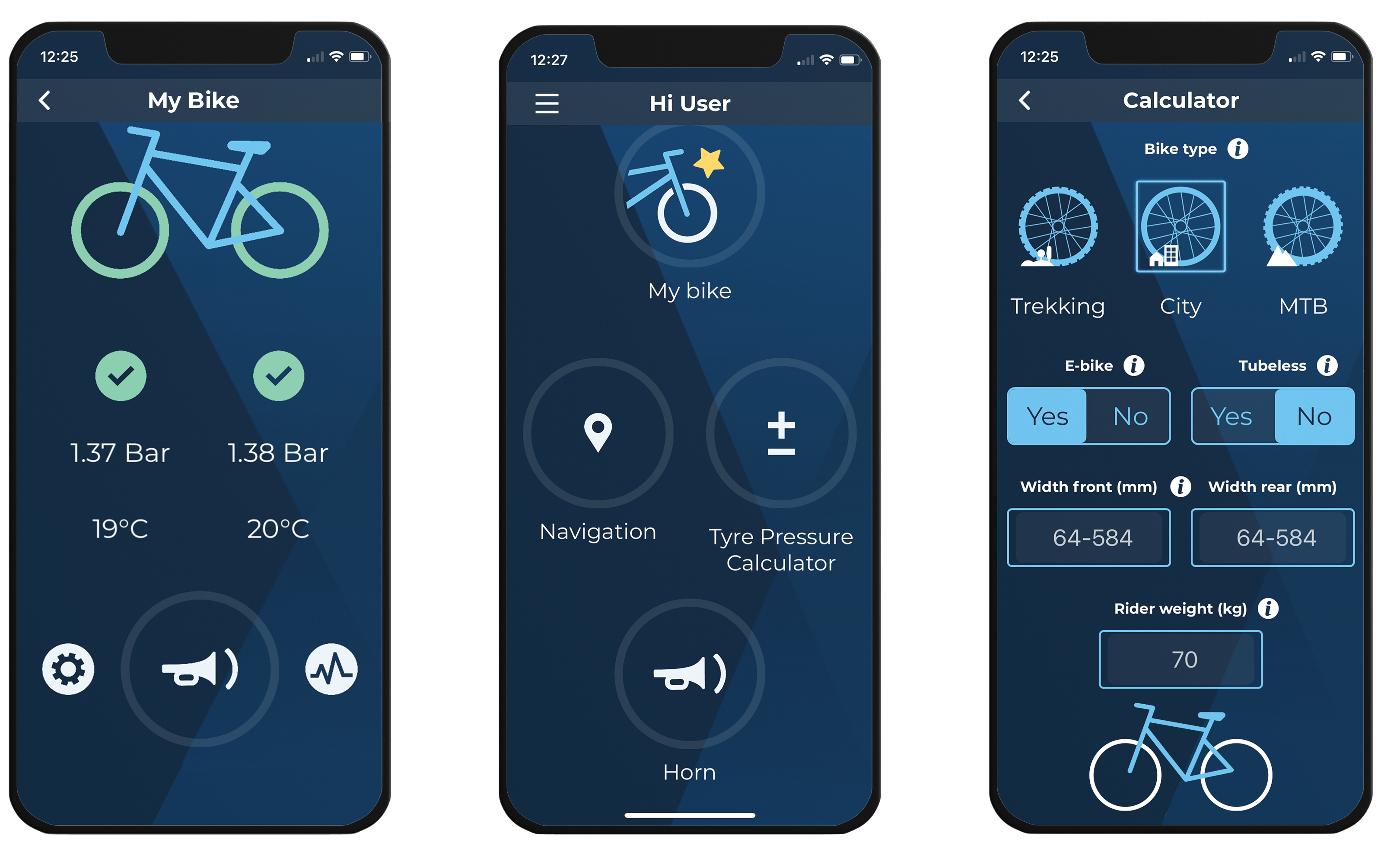

“The way bikes are used in everyday life has changed, and so have the requirements and needs. In future, digitalisation will be even more noticeable in many of our product groups. You can already see it in high-precision digital pressure gauges, the Compit handlebar mount with integrated power bank and gadgets such as the Airspy tyre pressure sensor. The market is leaving room for creative IOT possibilities. Products are also gaining a more multifunctional character, such as an MTB mudguard with integrated lighting. There is still a lot of improvement and progress possible.”

Because we are deeply rooted in the German region of Sauerland and also produce there, we could - and can - guarantee delivery”

In what way has production in Germany helped you during the corona pandemic?

“The bike industry has relied on supplies from the Far East in recent decades. But during the corona pandemic, it became clear that the foundation underneath was not solid enough. Because we are deeply rooted in the Sauerland region in Germany and also produce there, we could - and can - guarantee delivery. Our production was not hindered during the pandemic. We hardly had any corona cases in the factory. Due to the lockdown, we only had a slightly lower production for one month at most. The production in Germany combined with the good infrastructure towards many European markets means that the trade could always count on us.”

Do the corona struggles play into the hands of SKS Germany?

“We have been an important supplier to bicycle manufacturers for years and are also strong in the aftermarket sales. The corona pandemic has further increased the demand. Bike manufacturers see the advantages of production in Europe compared to the Far East, with the disadvantages of unstable quality, logistical struggles and high CO2 emissions. Demand has risen so much that we cannot take on new OEM orders until May 2023. We have therefore decided to increase capacity in our factory. We have invested in a new extrusion line for mudguards. This doubles capacity. These mudguards are intended purely for OEM applications. We are doing our best to scale up production even further and are already building a new warehouse. It is important that we continue to have sufficient staff for all this. At the moment, there are dozens of vacancies, especially in production and logistics.”

This article was sponsored by SKS Germany