Nijland’s challenge: connecting one battery with all electrical points on the e-bike

“With many of our customers we see that e-bikes tend to have more and more electrical systems on board. Connecting them all to each other is often quite a challenge”, comments Jannes Christiaensen, account manager at A&C Solutions. This also was the case with Nijland Cycling.

The Chariot e-cargo bike from Cargo Cycling, the cargo bike brand from Nijland Cycling, integrates flashing lights, electrical locks, a GPS system and lighting in the container. Nijland was looking for a solution to connect all of these electrical systems together. “For our e-cargo bike Chariot we wanted to use the GreenPack battery on the back of the bike to supply all the other electrical connections on the bike with power”, explains Gert-Jan Hallink, product developer within Nijland Cycling.

Based on the specifications and a blueprint of the project, A&C Solutions designed a fully customised cable harness with splitters and Higo e-bike connectors.

A day’s installation work becomes just one hour

Before switching to customised cabling, Nijland’s mechanics still had to provide all the cabling themselves, do all the stripping, soldering and connecting everything one by one. This was quite a labour-intensive process. The new solution with Higo connectors saves a lot of costly installation time. Gert-Jan: “It’s now much easier for our mechanics to do their job. A day’s work now has become just an hour’s work, maybe not even that.”

More reliable and faster maintenance with Higo customised cabling

This customised harness not only saves a tremendous amount of time in production, but also provides a quick and reliable solution in case of repairs. Gert-Jan confirms: “If the bicycle needs maintenance or something needs to be replaced, we are done much faster as well. And we are also 100% sure that it has been done correctly. And that makes us very happy!”

Connector expert from design to delivery

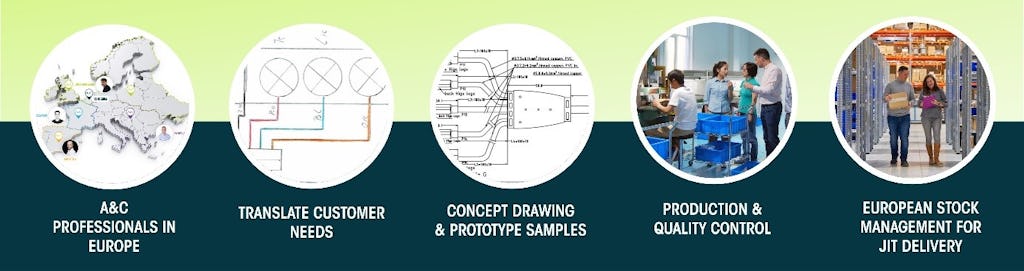

Projects like Nijland Cycling are examples where A&C Solutions’ specialism in both connectors and cabling makes the difference. It is the European partner for Higo connectors and has the technical expertise and the local availability of specialists inhouse to assist e-bike (component) manufacturers with the translation of their connector and cabling needs into fully customised solutions with Higo connectors. With a 1,000m2 warehouse located centrally in Europe, A&C Solutions is the e-bike connector expert from design to delivery.

This article is sponsored by A&C Solutions in cooperation with Higo connectors.