Growing demand for customisation

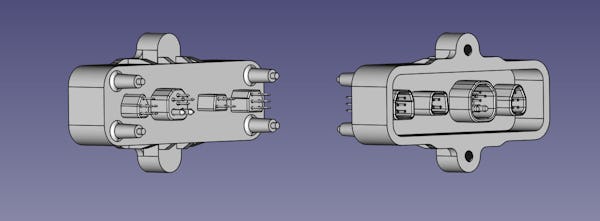

More and more e-mobility designs require more complicated, tailor made connections. A good example to meet this growing demand, is Higo’s customised connector rail. This plug and play rail works as a central point within the e-bike system that connects all parts together. The major advantages of working with such a rail are the reduced installation and service maintenance time. You easily replace a part and plug it in again.

Higo fully customises these connector rails according to the requirements of each e-bike design. It allows you to combine signal and power connections. And to choose the angled, solder or PCB contacts you need. This of course offers a great deal of flexibility to the customer. How does Higo organise this?

Full in-house manufacturing

In their production sites of 50,000 m2 in total, Higo takes care of the complete cabling of any type of e-bike, cargo bike or e-scooter for customers around the world. All of the connector related processes are manufactured in-house, from the production of cables, tooling and the single-handedly turning of contacts until the complete assembly of connectors. This already shortens the production chain and hence the lead time substantially.

New technology and machinery to enhance customisation

Investments in emerging technologies like 3D printing and the automation of production processes further enhance Higo’s power to customise connector solutions to the needs of each customer without compromising lead times. This facilitates Higo in the manufacturing of complete cable sets, splitters, assemblies with a combination of Higo and other brands’ connectors and connector rails of course.

Smart supply chain management

Located close to its customers in Europe, A&C Solutions is Higo’s partner to ensure a high-speed supply chain of Higo connectors. This is done by keeping local stock levels of Higo’s standard connector range and by offering customer specific stock possibilities to support a just-in-time delivery. A&C Solutions works with high volume imports and smart transport sourcing which also helps European Higo customers to save money on in-house stock and high import duties. Read more

The customisation strategy that Higo & A&C Solutions follow together works because of large scale in-house operations driven by innovation, automation and a strong supply chain focus.

This article is sponsored by A&C Solutions.