With the e-bike market expanding rapidly and consumers worldwide embracing the shift to cleaner, greener mobility, bicycle manufacturers are more in the spotlight than ever. This applies all the more as strong economic growth is predicted for the bicycle industry over the next decade, despite the current supply bottlenecks. After all, quite a few experts assume that e-bike sales in Europe alone will continue to multiply until 2030.

“The e-bike is certainly one of the trend-setting products at the moment. However, my observation is that we as an industry are slowing ourselves down a bit,” says Zhu. He is the CEO of the Timyo Group, a Netherlands-based company that designs, develops, jointly manufactures, and sells electric bicycles, mainly under its brands Van Dijck, Keola and Muon. “There are a few companies that dominate the supply chains through their big market shares. And at the same time, their standards and technology very much define what an e-bike has to look like. We want to change that,” he continues.

From assembler to innovation driver

When speaking to Zhu, you can immediately feel his enthusiasm and determination – a determination that is very well reflected in the rapid development of Timyo over the last few years. Since its foundation in 2015, the company has not only developed into an international player but also quickly earned a reputation for producing high-performance, stylish electric bikes that cater to a wide variety of users. Combining sleek design with functionality, the company’s bikes have become popular choices for commuters, leisure riders, and fitness enthusiasts alike.

“However, as the industry evolves, we have adapted our approach to ensure that we stay ahead of the curve in this competitive space,” Zhu explains. “That is even more the case as we have to overcome challenges such as supply bottlenecks, the global economic situation or the structures in the bicycle industry that have already been mentioned.”

The CEO refers to several strategic decisions in the last few years that have transformed Timyo from being an assembler to a company that is now on the verge of becoming a trendsetter in the industry regarding e-bike design and technology.

R&D driven

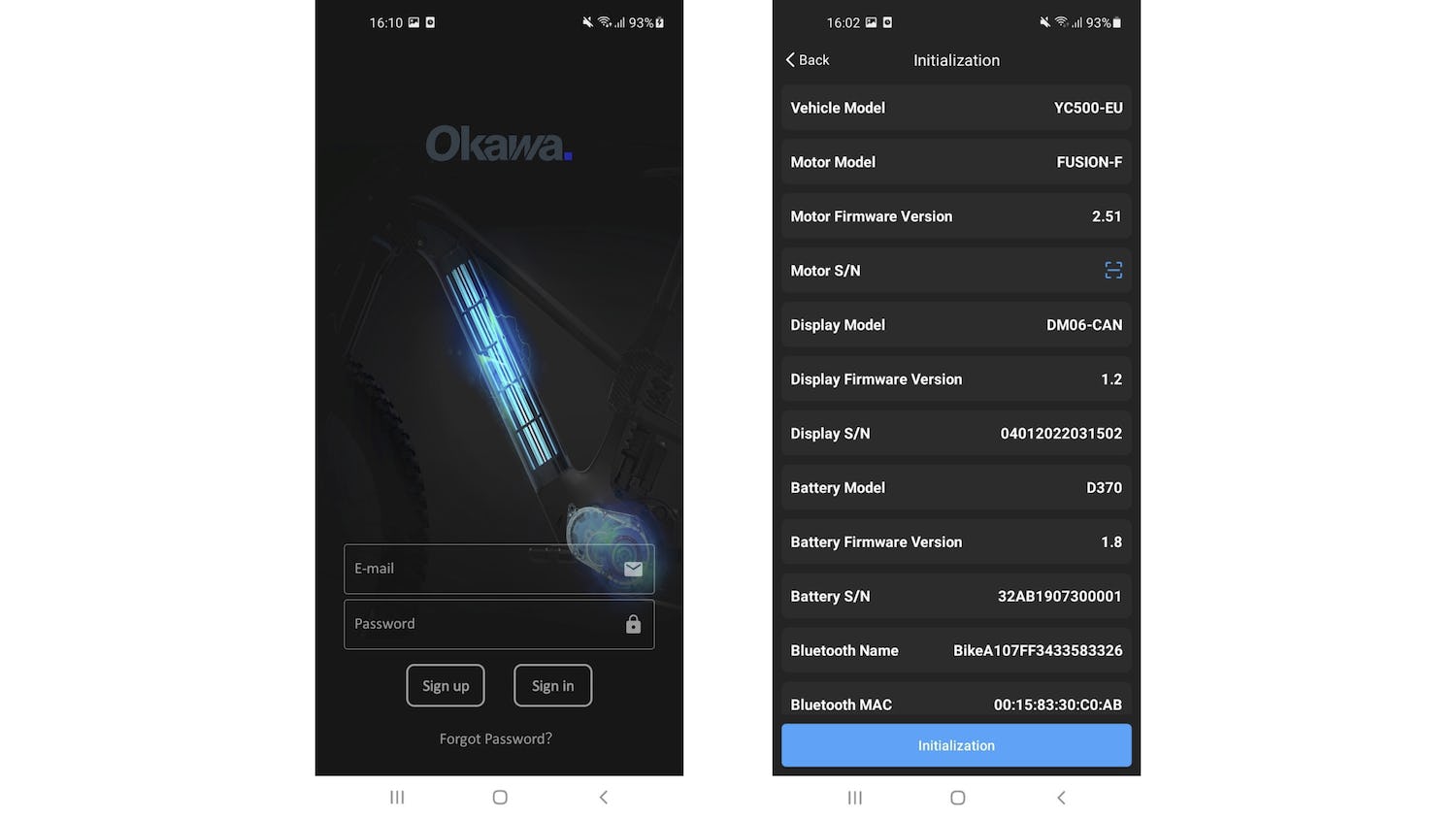

To overcome supply chain bottlenecks, Timyo opened its own frame factory in China, a subsidiary of Timyo’s owner, Nantong Dingyu Vehicle Industry CO. LTD., and assembling facilities in Lithuania and the Netherlands. Additionally, by realising the potential for growth and the importance of innovation, Timyo has also started a strategic shift to focus more heavily on R&D. This decision reflects the company’s desire to drive the industry forward, pioneering new technologies and solutions that will make e-bikes an even more viable and attractive transportation option.

Zhu gives insight into what this strategic shift actually looks like: “By having big brands defining standards, etc., many e-bikes today look very similar. But we are confident that this will change in the future. Therefore, we are working hard on redeveloping components and redefining their design. The result of these efforts will be e-bikes that will be smarter, more integrated, and easier to assemble,” he says, predicting that the new strategy will also make Timyo more competitive when it comes to the pricing of the bikes. “Since we now have everything in-house – from R&D to assembly – we can also produce at lower costs without compromising quality. And we are less dependent on others. That will surely be another boost for our development.”

This article was sponsored by Timyo.