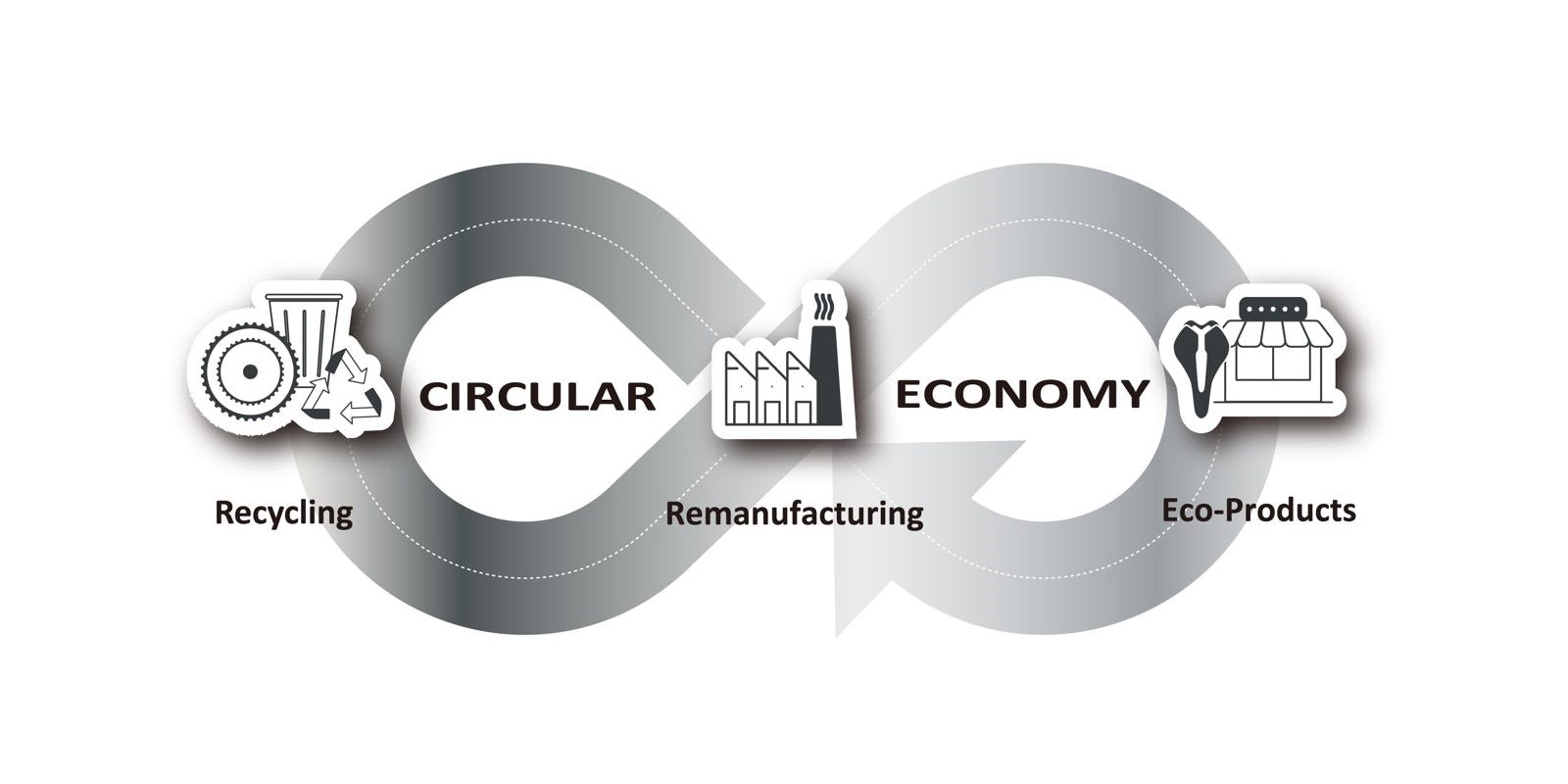

“At Velo, we define circular economy into two simple categories — external and internal,” explains Ann Chen, general manager. “Internally, our circular economy emphasises recycling, reusing, reducing and redesigning. This involves recycling materials that can be repurposed, minimising unnecessary packaging and resource consumption, and redesigning products with ESG (environmental, social, and governance) principles in mind. Over the past decade, we have been dedicated to achieving these goals. We are proud to share our accomplishments and our progress.”

Collaboration for a circular economy

“This year, alongside our internal efforts, we have strengthened our external collaboration with SRAM,” continues Chen. “We believe that expanding the circular economy in this way creates equal value and a mutually beneficial outcome. We also believe that the circular economy should maintain equal value. For example, recycled waste should be used in products of the same value rather than downgraded into secondary products. Otherwise, the depreciation in value is not aligned with our vision.”

SRAM is a renowned supplier of bicycle components, with its primary production facilities located in Taiwan. It is the company’s mission to create products and experiences that inspire cyclists. One of its most well-known brands is Zipp, which specializes in producing lightweight carbon components including wheelsets, handlebars, stems and seatposts.

Carbon fiber components

“Carbon fiber components have gained significant popularity in the bicycle industry due to its lightweight properties and performance benefits,” mentions Chen. “However, the waste and losses generated during the manufacturing of carbon fiber products can pose challenges for recycling. Although SRAM already had an excellent system for recycling carbon waste, there were still some questions, such as: Where do these recycled materials go? Do they retain the same value in production? These questions were addressed through the company’s collaboration with Velo.”

Performance-driven saddles

With over 45 years of experience in the bicycle industry and a production of 12 million saddles annually, Velo has been dedicated to exploring alternative materials that can replace current ones to help reduce the carbon emissions of its products.

The collaboration between these two industry leaders led to a solution that combined SRAM’s carbon fiber waste with nylon to create Velo’s performance-driven saddles. Chen adds: “This new material has undergone testing and has been verified for use in our production.”

Reducing carbon emissions

“Both SRAM and Velo have successfully maintained the value of the materials while reducing carbon emissions together,” explains Chen. “A key factor in this achievement is the proximity of our factories in Taiwan. They are located less than 20km apart. In addition, our performance saddle made with recycled carbon fiber reduced carbon emissions by 380 to 785 grams. That is solely due to the use of these fibers!”

SRAM and Velo share a common goal in ESG. “We strive to grow together while making progress in our individual efforts,” concludes Chen. “In the industry, we both aim to establish a circular economy model in the production of bicycle parts and accessories.”

This article is sponsored by Velo.