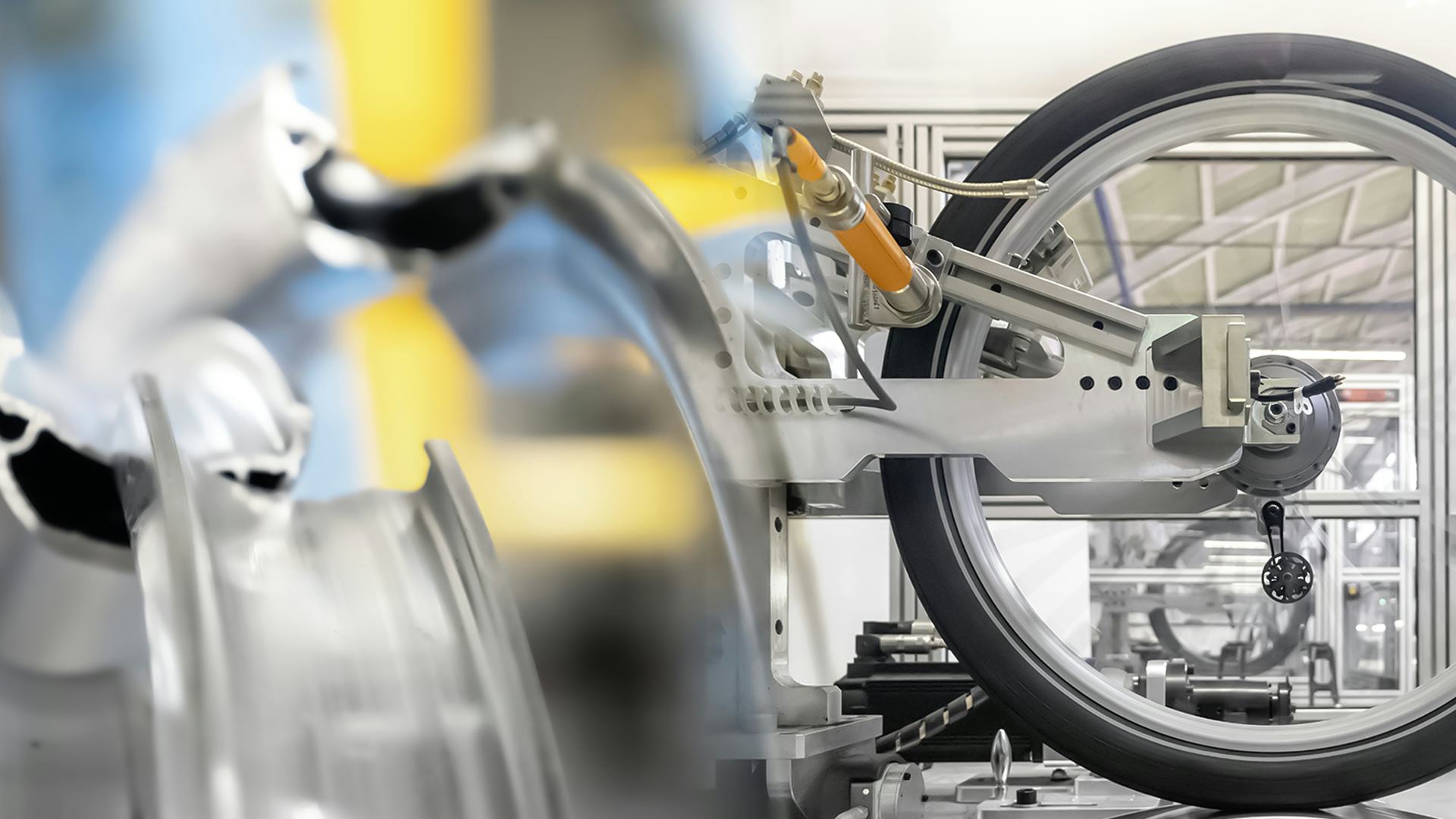

It takes just a few moments for one of the robotic arms to form metal strips into rim beds and then into wheels. “Most of our production is done manually, but in the recent past, we have also invested a lot in automated equipment,” says Duarte Bernardo while giving us a tour through the headquarters of Rodi Industries. Here, in the Southern part of the Portuguese city of Aveiro, also known in the industry as the capital of the Portuguese Bike Valley, around 400 employees produce wheels and rims. In different production steps, workers and machines form rims into shape, install spokes and nipples, and glue decals onto the rim flanks. This way, roughly three million rims and about 400,000 wheels leave the Rodi production lines every year, mainly made of aluminium, suitable for a wide range of bicycle types.

“Currently, we are working on increasing our capacities,” Bernardo explains. “The reasons are, on the one hand, greater demand from customers, but also new models and product lines we are currently working on,” the Portuguese continues and refers to Rodi’s newest product category: rims, specially tailored for cargo bikes.

Hard-wearing and robust

Being able to carry loads of up to 250 kilograms, the new 'Brutus' rims are exceptionally hard-wearing and robust. Specific manufacturing processes and technological options like single or double eyelets as well as dimple hole capsules are implemented to further increase the stiffness and strength of the rims. “Additionally, we implemented a specific finishing that should reduce the risk of scratches. Especially for vehicles in the transport sector, this is a crucial factor since durable wheels also reduce the maintenance times and costs,” Duarte adds.

New factory

A new wheel series, specially designed for cargo bikes and electric transport vehicles – the market introduction of the new 'Brutus' rims shows that the ambitions of Rodi Industries are high. That is also reflected by the fact that the Portuguese manufacturer is about to finish the construction of a new production facility for its cycling business, which will be completed by the end of this year, as Bernardo says at the end of our factory visit at the Rodi headquarters in Aveiro. The new factory will not only allow for the optimization of the flow and production capacity but will also lead to the installation of a new anodizing line, which will improve the quality of the products and open the door to the production of other bicycle and e-bike-related products. Products like the cargo bike wheel series 'Brutus'.

Duarte Bernardo: “We presented the new wheels at the Eurobike show in Frankfurt this summer. The feedback from our partners was excellent. However, what made us particularly proud was the fact that also many new companies showed interest. Companies that we have never worked with before and that don’t have their roots in the traditional bicycle industry. For this reason, we are very enthusiastic about the future.”

This article is sponsored by Rodi.